STEEL ABRASIVES

Steel Abrasives are mainly used for two applications. 1. Surface Preparation industry and 2. Stone cutting industry.

STEEL SHOT

Steel shots are spherically shaped product made of carbon steel and manufactured by melting of scrap in induction furnace. To obtain the SAE standards the molten metal is analyzed for chemical composition and strictly controlled by spectrometer. It is then atomized and transformed to round shaped and subsequently quenched and tempered by heat treatment process to provide uniform microstructure, density and required hardness coupled with good toughness for durability. And it is then screened to SAE standard specification.

Steel shot is widely used on wheel blasting equipment. It can also be used in open blasting for descaling of steel component prior to coating, shot peening, deburring etc. Another industry application for steel shot is in foundry to remove sand from castings and clean after the removal of moulds.

If used in proper equipment, steel shot will turn to be the ultimate economical abrasive blasting media for surface preparation due to its durability as it can be recycled number of times. The consumption rate of abrasive for blasting using steel shot will very less comparing any other blasting media. Rate of breakdown is very low and hence the dust generation while blasting will be also significantly less.

STEEL GRIT

Steel Grit is manufactured from high carbon steel shot which are crused to angular shape by special roll mill and subsequently tempered to different hardness grades (GH, GL & GP) for different blasting applications. Finally, each hardness grades are screened to different abrasive mixes.

Sharp Angular shape and relative hardness of Steel Grit leads to high cleaning rates and recyclability hence, it is an excellent abrasive for blasting operation in closed environment such as blast room and open blasting . Industry application of steet grit as blasting media includes, descaling of steel structures, granite cutting, and surface roughness before blasting and painting. Steel Grit can be recycling number of times.

Chemical Composition Technical Specification

Carbon |

0.85 – 1. 20 % |

Features |

Shot |

Grit |

Manganese |

0.35 – 1.20 % |

Hardness |

40- 51 HRC

SAE std

J827-Sep/96 |

GP 40-51 HRC

GL 54-61 HRC

GH ≥ 60 HRC

SAE Std

J1993-Sep/96 |

Silicon |

0.45 – 1.50 % |

Density |

≥ 7.0 g/cm³ |

≥ 7.3 g/cm³ |

Sulphur |

< 0.05 % |

Microstructure |

GL, GP – Finely Tempered Martensite

GH – Martensite |

Phosphorous |

< 0.05 % |

Shape |

Round |

Angular |

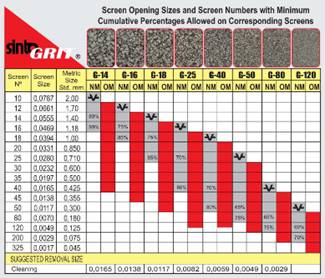

SAE SHOT AND GRIT SIZE SPECIFICATION WITH SUGGESTED REMOVAL SIZES.

Abrasive Sizes and general applications

Packing

| 25Kg Bags |

1 Ton Bags (40 Nos x 25Kg Bags) Palletized |

|