DUST FREE BLASTING SYSTEMS

The cleanest and most economical blasting method

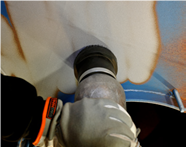

With a new range of vacuum blasters, Nederman takes blasting technology one step further by eliminating the traditional drawbacks of blasting. It is a completely dustfree process where the surrounding area is not exposed to flying blasting media. The blaster can therefore be used in premises where other activities are going on without disturbing them.

The unit is mobile and can be easily moved for use indoors, outdoors and in confined spaces where conventional blasting is not permitted.

Nederman’s vacuum blasters also of advantages. The blasting agent is automatically drawn back into the unit, where it is cleaned and recycled as part of the process. Work can be carried out more effectively with fewer interruptions for refilling of blasting agent and the premises do not have to be cleaned after work.

Benefits of Dust Free Blasting

DUST-FREE AND SAFE

• Clean and interruption-free for work colleagues and surrounding area

• Does not require screening or special protective equipment

• No need of Blast Room

ECONOMICAL

• Blasting media can be reused at least 3 times

• No post-cleaning required

ENVIRONMENTALLY FRIENDLY

• Blasting replaces chemicals and rust agents

• All approved blasting media can be used, e.g. glass beads , steel grit , al oxide and nutshells

• The air from the unit is purified and can be returned to the premises

• Blasted material is collected in a waste bag

FLEXIBLE

• Compact, mobile unit – easy to move between work stations

• With a simple manoeuvre, the function of the Vacuum Blaster can be changed so that it can be used for collection of blasting abrasive from a smaller blasting room

• The vacuum unit can be operated either electrically or by compressed air. |

sales@clean-blast.com

sales@clean-blast.com